Constant Force Springs

Stable Output for Long-Travel Applications

Constant Force Springs | Stable Output for Long-Travel Applications

Our strongest selling points are our custom design capabilities, in-house tooling services, manufacturing, a wide and varied stock spring selection, and our commitment to quality and on-time delivery.

Applications of Constant Force Springs

Our constant force springs are vital components in a wide variety of industries, such as:

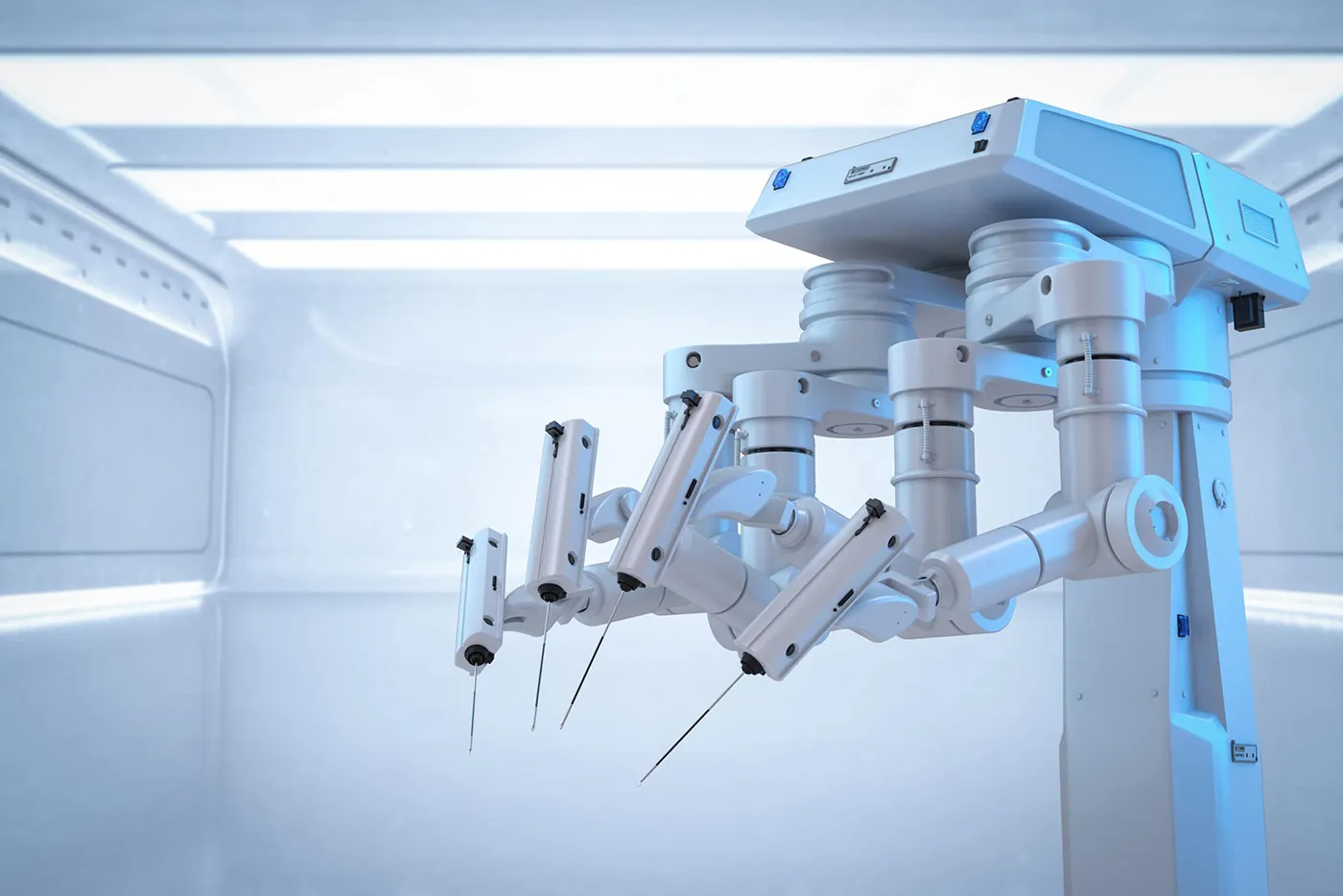

Surgical Devices

Windows

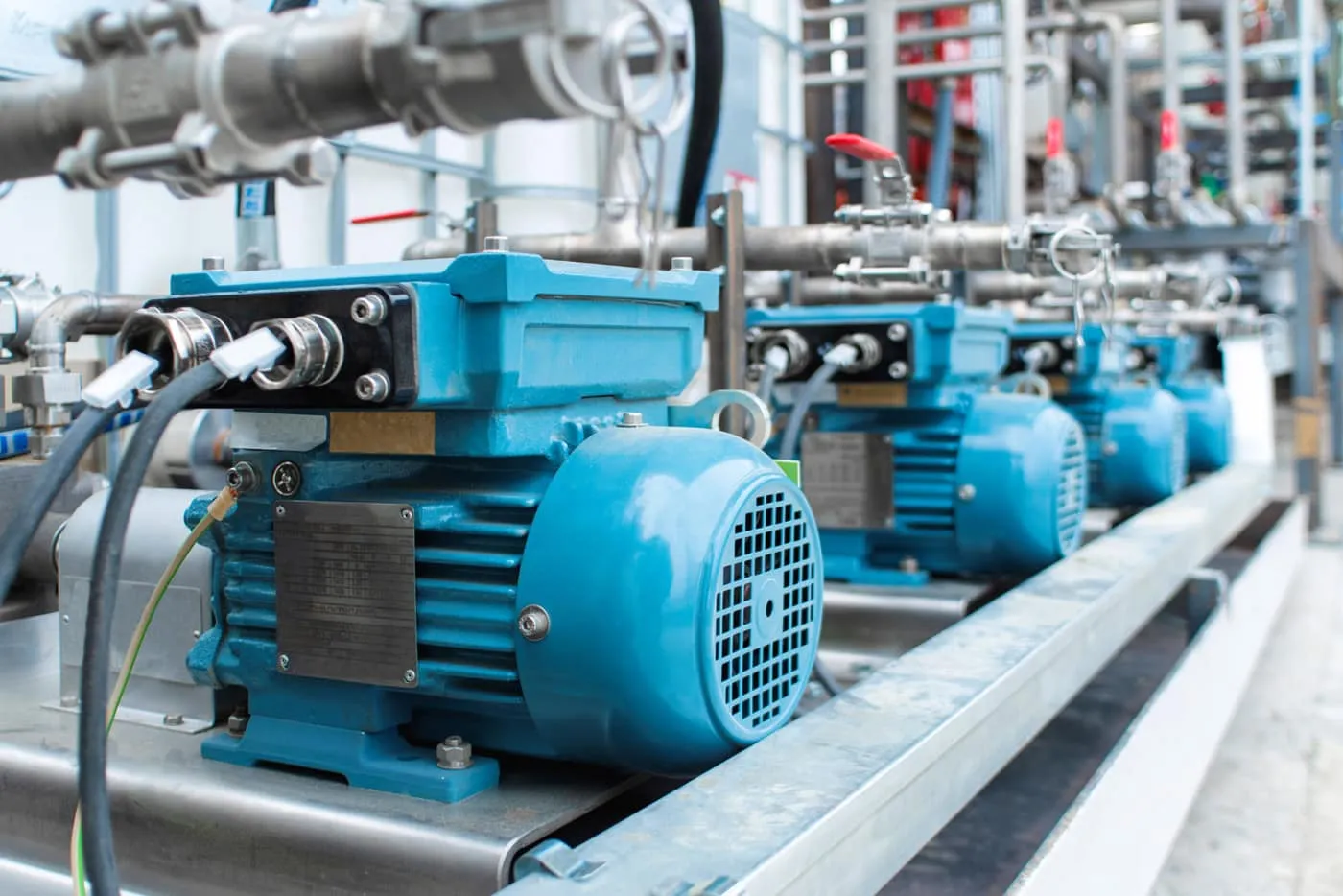

Electric Motors

Fire Dampers

Gym Equipment

Benefits Of Constant Force Springs

Where Great Work Meets Great Rewards

Strong Force Yield Within Small Spaces

Mounts Easily to Existing Hardware

Smooth, Uniform Load Throughout the Entire Length of Travel (Deflection)

Extensive Linear Range

Compact Size

Constant Force Springs

A constant force spring provides a smooth, uniform load through its full length of travel. This type of spring comes in compact package sizes, offers extensive linear range, and yields strong force within confined spaces. It also easily mounts onto existing hardware.

Click to expand the graphic and see how the spring can interact with your products.

Full Extension & Spring Load

Once the spring is extended to a length of 1.25x its diameter, it reaches its maximum load and can maintain this constant force regardless of how far it extends or retracts. The spring’s load only depends on the diameter of the spring and the width and thickness of the material.

Materials

The material selection for a constant force spring application is essential in determining the project and design costs. The best constant tension spring material varies depending on the type of environment it will be used in, such as corrosive and high-temperature environments, which can also affect the overall life of the spring and selected material.

The following materials are commonly used in the construction of the physical spring:

301 Stainless Steel

An austenitic chromium-nickel type of stainless steel that can be cold-worked to achieve high ductility and tensile strength. It does not harden by heat treatment, and although it is not magnetic in the annealed state, it does become magnetic with cold deformation.

Inconel

Inconel springs are ideal for use in corrosive environments exposed to salt water, aggressive air, or aggressive water conditions.

High Carbon Steel

Features significant hardness, due to more than 0.3% carbon content.

Mounting Methods

There are several mounting methods, and your application will determine which mounting method is best for your spring’s design. A constant force spring typically gets mounted by wrapping it tightly on a drum and then connecting the free end to the loading force. The relationship is also easily reversed.

The diameter of the drum should be larger than its inside diameter by 10% to 20%. Long extension applications may cause the strip to become unstable, requiring guidance to prevent recoil, kinking, or twisting. At maximum extension, one-and-a-half wraps should still be on the drum.

Idler pulleys need to have a larger diameter than the natural diameter and should not create back-bending against the curvature’s radius.

Performance Considerations

The life of a constant force spring is rated by the number of cycles it can perform before it begins to break, warp, or exhibit inconsistent constant return force. Springs are typically rated from 2,500 cycles to more than 1 million cycles.

The spring life varies and is dependent on the specific application as well as the following performance considerations:

Help meet specific force and durability requirements within the spatial constraints. A thicker material with a smaller coil diameter could provide a higher force, but it might also wear out faster, whereas a thinner material with a larger diameter could last longer but deliver less force.

Maximizes force output, enhances durability, and ensures long-term reliability under various environmental conditions.

Crucial in preparing constant force springs for specific applications, especially in industries requiring precision and safety due to the handling and exposure of the strip edges. Optimizes the performance, durability, and safety of the spring.

Understanding the specific chemical environment and selecting materials and coatings accordingly are critical steps in ensuring the reliable performance and longevity of constant force springs in chemically aggressive environments.

Depending on the temperature conditions a spring will face selecting the appropriate material and design features is vital. Ensuring the spring performs reliably across the intended temperature range.

Significantly affect the performance of constant force springs by introducing dynamic forces, vibration, wear, and potential heat-related issues.

Affects everything from force consistency and resistance to environmental factors to the spring’s ability to withstand mechanical stresses and maintain its integrity over time.

Can negatively affect the performance of constant force springs by causing force inconsistencies, misalignment, increased wear, reduced load capacity, and operational noise.

Improves the performance and longevity by reducing friction, wear, and other negative factors.

Constant Force Spring Design Considerations

There are many design factors that will affect the time and cost needed to manufacture your spring. Therefore, it’s important to work with a manufacturer like LEADING SPRINGS that has the knowledge required for the design phase.

◉ Mounting Methods: There are several mounting methods. Your application will determine which mounting method is best for your spring’s design.

◉ Material: The material selection is an important component of the design and project cost. The optimal spring material is often different in high-temperature and corrosive environments. Material will certainly affect the design and project cost. High temperatures or corrosive environments will also affect the life of a spring and the required material.

◉ Diameter and Load: Length, material width, thickness, and coil diameter affect the spring’s load. Increased loads can be obtained by using two or more constant force springs interwound, in tandem, or in other configurations.

All of these, plus other technical considerations, need to be discussed and specified prior to creating prototypes. Our design engineering team can help ensure calculations and configurations are exact in the design phase.