Cable Spring

Controlled Retraction for Dynamic Systems

Fast response and controlled motion solutions for dynamic applications

Our cable spring solutions are engineered for long-travel, repetitive-motion, and space-constrained applications, delivering consistent pulling force throughout the operating range.

Applications of Cable Springs

Our constant force springs are vital components in a wide variety of industries, such as:

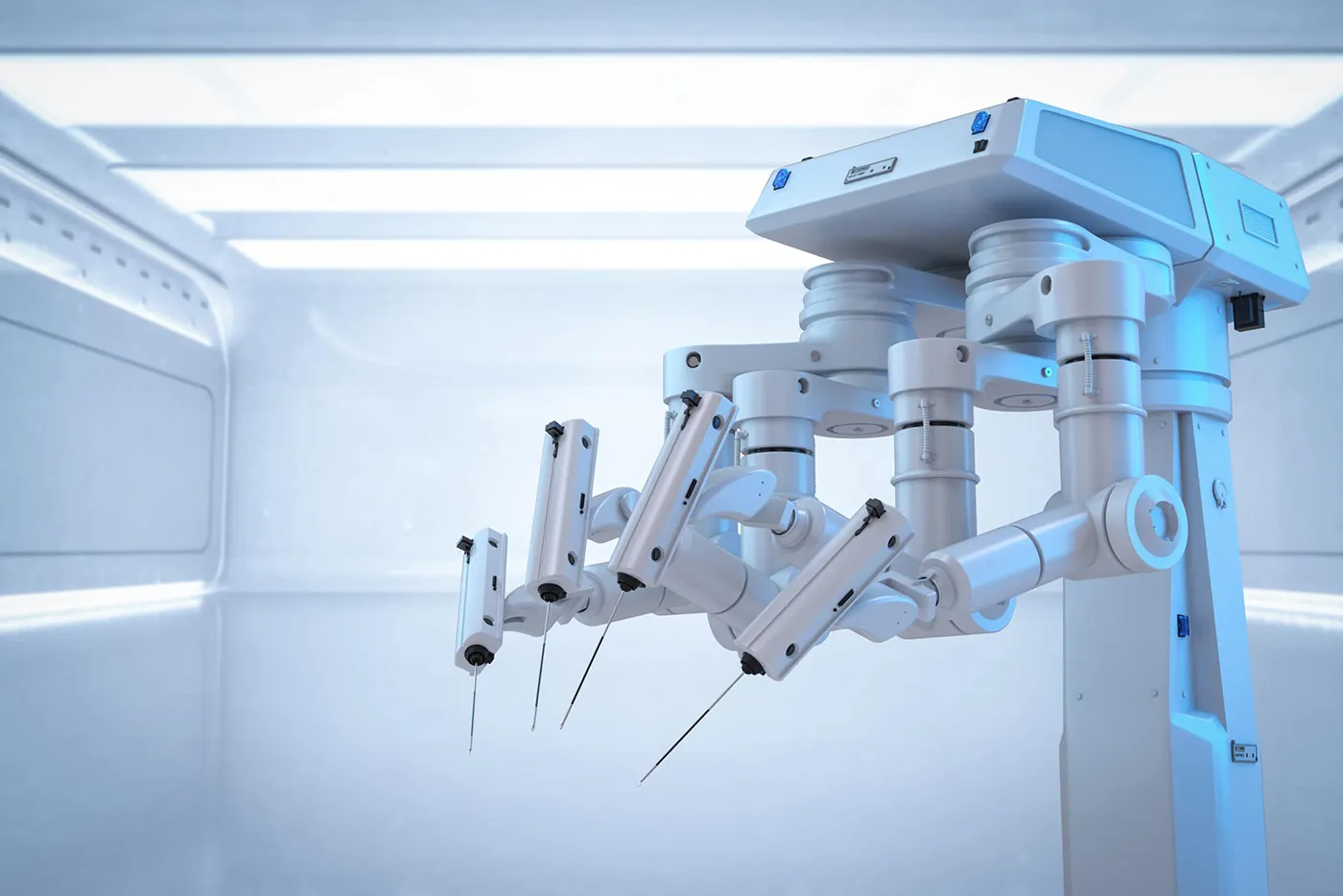

Industrial Automation

Gym Equipment

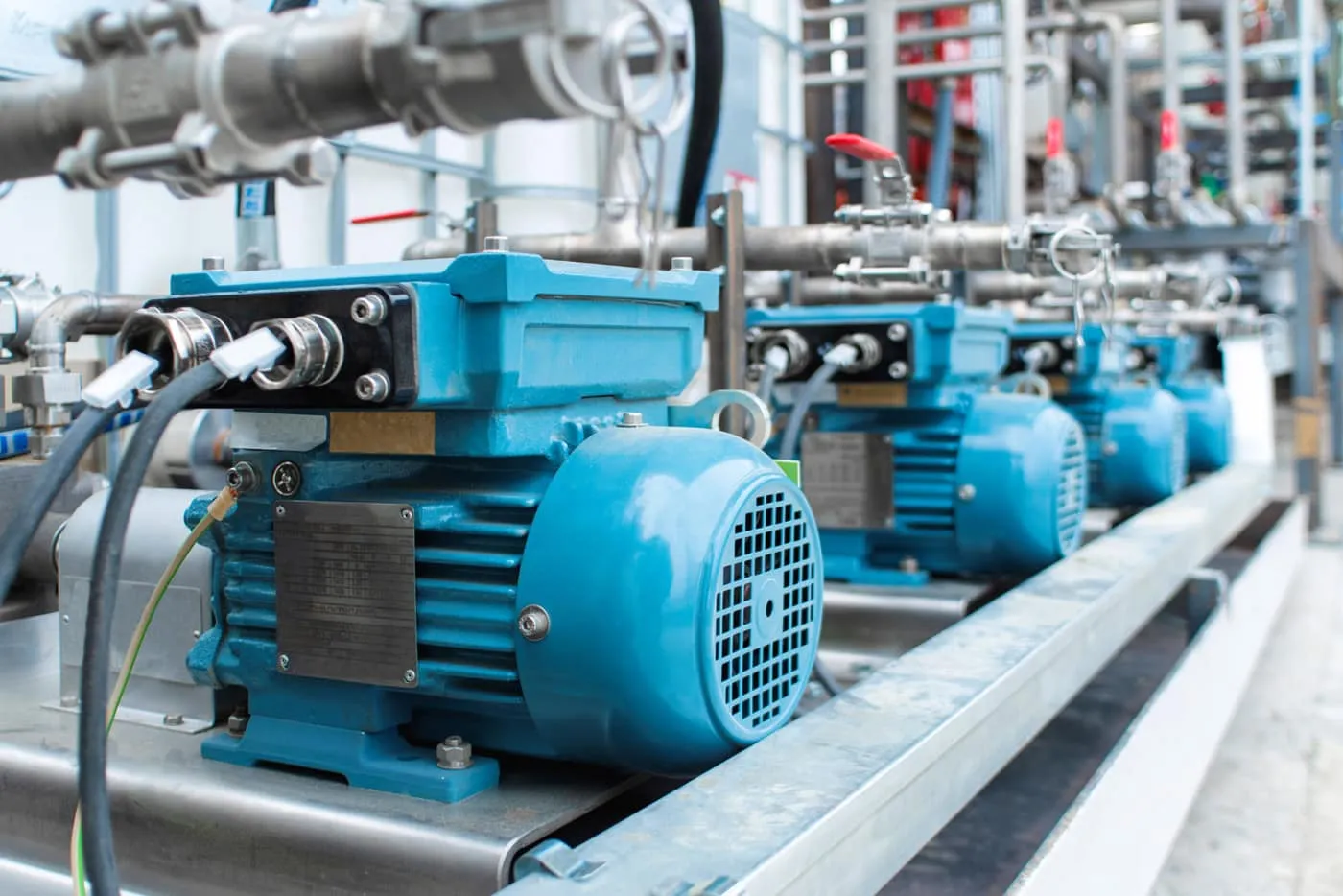

Electric Motors

Fire Dampers

Benefits of Cable Springs

Where Great Work Meets Great Rewards

Strong and Stable Force Output

Smooth, Uniform Motion

Compact Design

Easy Integration

Long Service Life

Controlled Retraction & Cable Management

Cable Springs

Cable springs store mechanical energy within the spring body and transfer it through a cable assembly, providing controlled pulling and retraction across the full stroke length.

Full Extension & Spring Load

Once the spring is extended to a length of 1.25x its diameter, it reaches its maximum load and can maintain this constant force regardless of how far it extends or retracts. The spring’s load only depends on the diameter of the spring and the width and thickness of the material.

Materials

Material selection is critical to performance, durability, and project cost. We offer multiple material options based on application conditions.

Stainless Steel Cable / Spring Steel

Ideal for applications requiring corrosion resistance and long-term stability.

Performs reliably in humid or mildly corrosive environments.

High Carbon Steel

Offers higher strength and force output, suitable for standard industrial and high-load applications.

Provides an excellent balance between performance and cost.

Optional Alloy Materials

High-performance alloys are available for high-temperature, corrosive, or demanding environments.

Mounting Methods

Cable springs can be installed using several mounting methods, depending on system design and operating conditions.

Drum / Spool Mounting

The cable is wrapped around a drum or spool, with the free end connected to the load.

This method provides smooth retraction and controlled travel.

Diameter & Extension Considerations

The drum diameter should generally exceed the spring’s natural inside diameter by 10–20%.

Long-travel applications may require guides to prevent instability or twisting.

Pulley & Guide Design

Idler pulleys should exceed the cable’s natural bend radius and avoid reverse bending to maximize service life.

Performance Considerations

Cable spring life is typically rated by cycle count and can range from thousands to millions of cycles, depending on design and application.

Material thickness and coil diameter directly affect force output and wear rate.

Thicker material and smaller coil diameters generate higher force but may reduce cycle life, while thinner material and larger diameters improve longevity at lower force levels.

Different materials offer varying balances of strength, corrosion resistance, and fatigue performance.

Material selection should reflect the operating environment and required cycle life.

Edge condition influences crack initiation and fatigue life.

Deburred or conditioned edges reduce stress concentration and improve long-term durability.

Exposure to chemicals, oils, or cleaning agents may accelerate corrosion or material degradation.

Chemical compatibility should be reviewed during the design phase.

Operating temperature affects material strength, elasticity, and fatigue behavior.

High or fluctuating temperatures may require specialized materials.

High operating speeds and rapid acceleration increase dynamic loads and wear.

These conditions may require additional safety margins or damping solutions.

System stability depends on proper alignment, guiding, and load direction.

Poor stability may lead to uneven wear, vibration, or inconsistent force output.

Reverse bending significantly reduces cable and spring life.

Designs should minimize backbend or eliminate it entirely where possible.

Proper lubrication reduces friction, wear, and noise in moving components.

Lubrication requirements depend on environment, speed, and material pairing.

Cable Spring Design Considerations

Cable spring design factors directly affect manufacturing time, cost, and system reliability.

Early collaboration with an experienced manufacturer is essential.

◉ Cable Path & Bending Radius: The cable routing and minimum bend radius determine fatigue life and smooth retraction. Avoid reverse bending and sharp transitions; use guides to maintain a consistent path under motion.

◉ End Fittings & Load Interface: End fittings define how load is transferred into the cable spring system. Specify connection type (hook/pin/threaded), allowable misalignment, and installation clearance to prevent side-loading and premature wear.

◉ Duty Cycle & Retraction Requirements:

Define cycles per day, operating speed, peak acceleration, and required retraction behavior (constant pull vs. staged pull). These parameters impact spring selection, cable construction, and safety margin design.

All critical inputs should be reviewed before prototyping to avoid multiple design loops. Our engineering team can assist with routing recommendations, interface selection, and lifecycle validation planning.